Updated April 06, 2025

About

I have been working on making my radio kit more packable, but the first issue I ran into was that my antenna didn’t easily fit in my bag. I was using an EFHW based on a 240-43 core inside a large junction box. I designed this antenna to be nearly pocketable and very quick to deploy. I’ve since found similar antennas for sale online, but I decided to still share this design since others are quite expensive.

The antenna is used somewhat like you may crank a reel on a fishing rod. You can unpack the wire by simply pulling it out while holding the outer shell, you can re-pack it by holding by the shell and cranking the center.

Parts required

- 20awg magnet wire

- 1x 140-43 Ferrite Toroid

- 1x 100pf 10KV Ceramic Disc Capacitor

- 1x SO-239

- 4x M3x20 Machine screws

- 4x M3 Nuts

- 5x M3x10 Machine screw

- 3x Small size zip-ties

- Various crimps for assembly, can be substituted with solder if you’re in a pinch

- Any antenna wire 14awg and smaller (speaker wire works)

Downloads

Please note that these designs are CC BY-NC-SA, so no commerical usage is allowed.

InnerCore.STL

OuterCore.STL

Shell.STL

Crank.STL

Assembly

- Screw OuterCore.STL and Crank.STL together with a M3x10 machine screw (back the screw out just enough that the crank can spin). Next loop a zip-tie through the two holes in the center and secure on the inside.

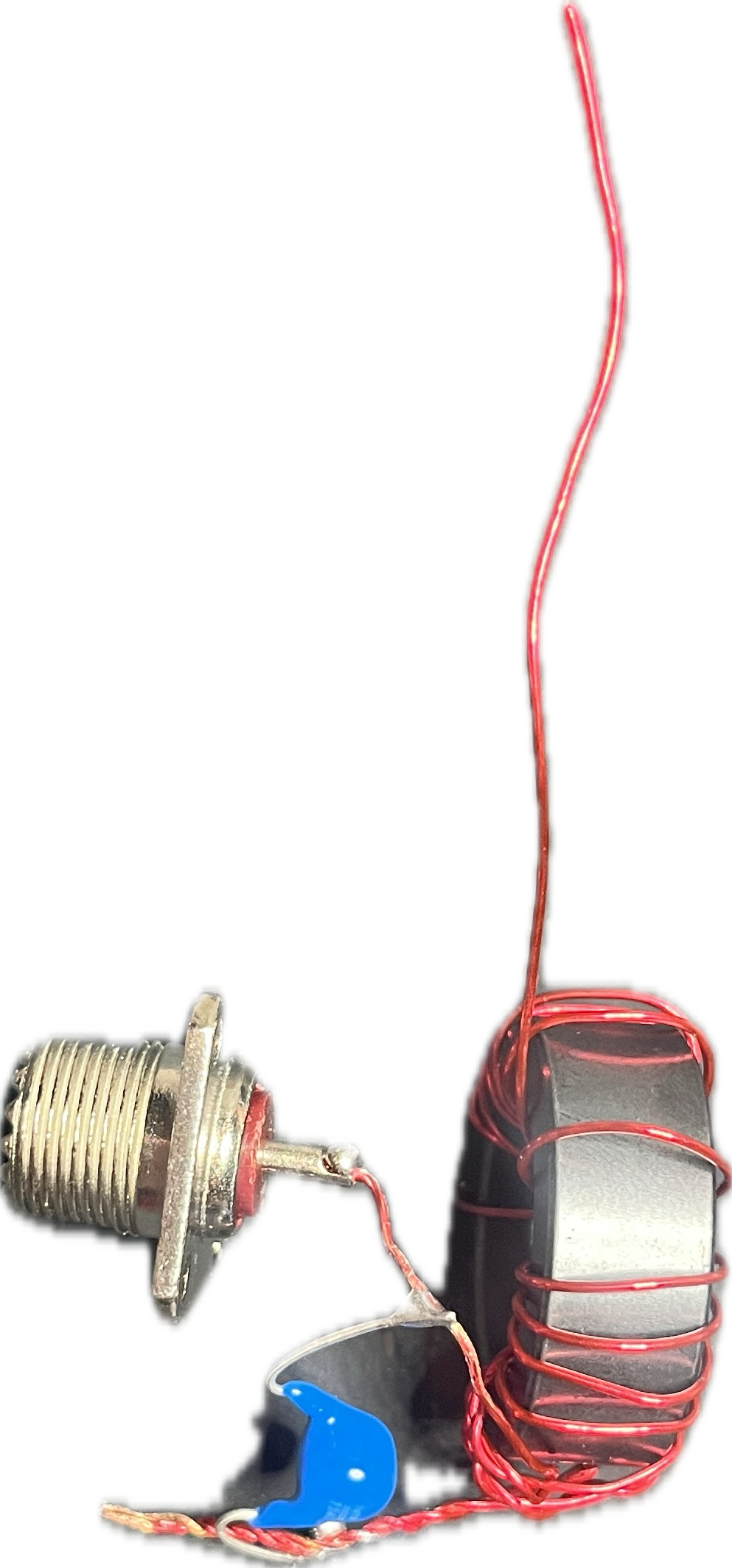

- Wind your toroid, and solder together with SO-239 & capacitor.

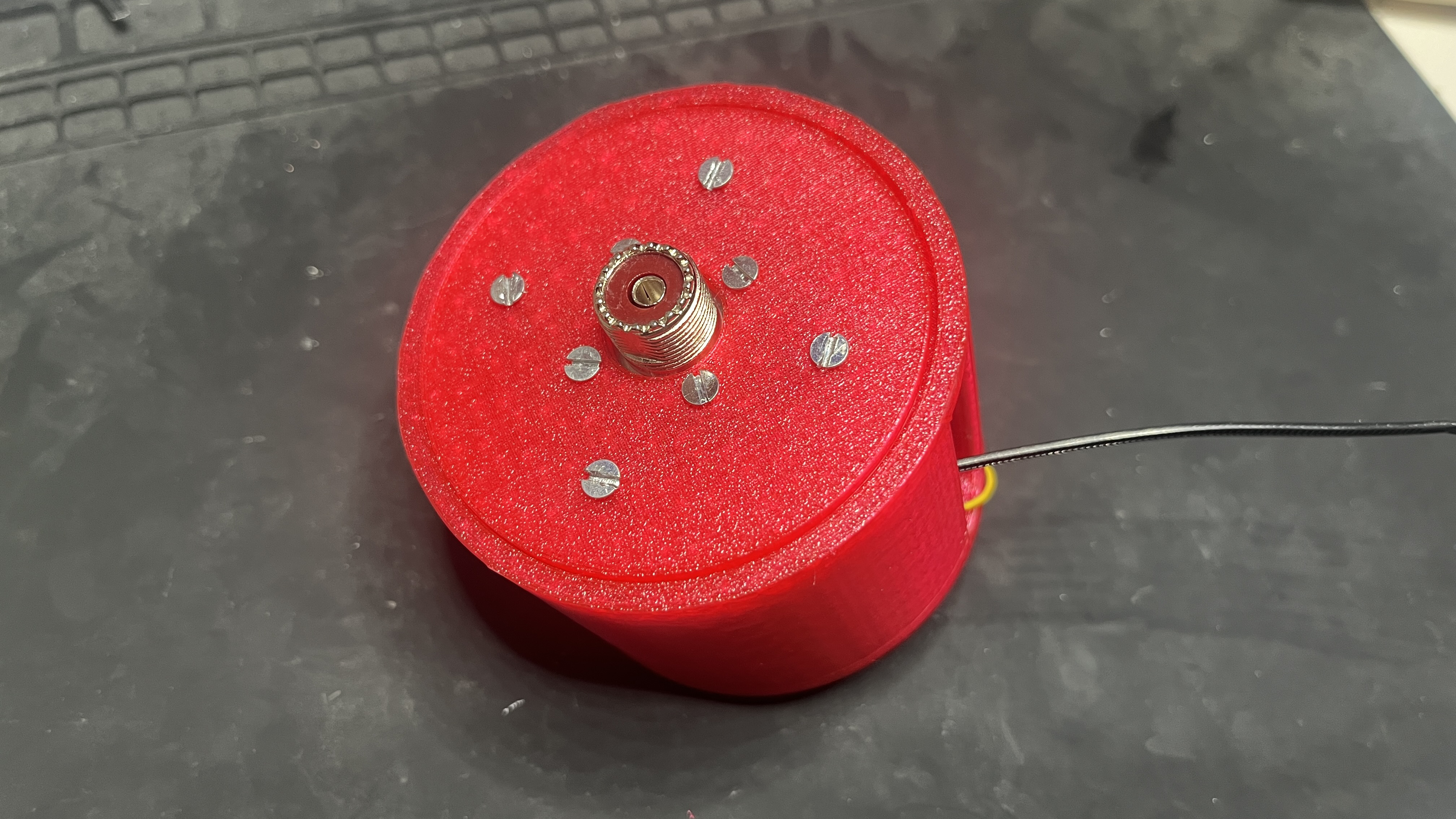

- Secure transformer into InnerCore.STL with two zip-ties, and secure SO-239 jack with four M3x10 machine screws and M3 nuts. Attach your ground to the shield of the SO-239 with a ring terminal connector at this point.

- Place Shell.STL over InnerCore.STL and thread your antenna wire through OuterCore.STL and out through the slot in Shell.STL (Make sure to create a knot for strain relief, this way the antenna doesn’t hang off of your crimp). Now place OuterCore.STL into the opposite side of the shell while pulling your wire the rest of the way through. Rotate both parts of the core around until the four screw holes line up viewed from the end with the SO-239 jack. Thread four M3x20 machine screws into the plastic, securing both sides of the core to one another.

Conclusions

I’ve been running this antenna in the field for 4 activations now. It’s held up very well printed in PETG, and is light enough to be supported by nearly any tree. It’s had no problem handling 100 watts, but you may want to stack two toroids if this is your use-case. I’ve only tested it with one toroid, but the design could probably fit two.